February 17, 2025

By Cavan Merski, data analyst, Pecan Street

Virtual power plants (VPPs) are a cost-effective, flexible solution to the challenges of balancing supply and demand on power grids. And they’re rapidly gaining traction in the energy industry.

Instead of relying solely on large-scale power plants and expensive utility infrastructure upgrades, VPPs aggregate and coordinate a range of smaller energy resources like batteries, solar panels, electric vehicles, and smart thermostats into a single, dispatchable resource. This coordination allows for adjustments in the balance of electricity supply and demand, which creates a more resilient, stable, and efficient grid.

When managed via smart thermostats, heating, ventilation, and air conditioning (HVAC) systems can be a particularly powerful piece of the VPP equation. By remotely adjusting thermostat setpoints in homes and businesses, VPP operators can fine-tune energy demand without significantly impacting occupant comfort. Automated shifts in heating and cooling patterns can create a collective response that rivals the capacity of traditional power plants. With millions of HVAC systems under management, even minor changes in thermostat settings can yield gigawatts of demand response potential.

Why thermostats? The appeal is twofold. First, smart thermostats are already popular, easy-to-install devices that customers understand and trust. This familiarity helps pave the way for wide-scale participation, especially if customers receive free installation and the promise of lower energy bills. Second, HVAC demand is one of the largest and most controllable aspects of residential and commercial energy consumption.

By slightly adjusting indoor temperatures — such as pre-cooling a home before an evening peak or letting a building’s temperature float by a degree or two during critical periods — grid managers can shift massive amounts of demand in real time without needing physical upgrades to transmission lines or new power plants.

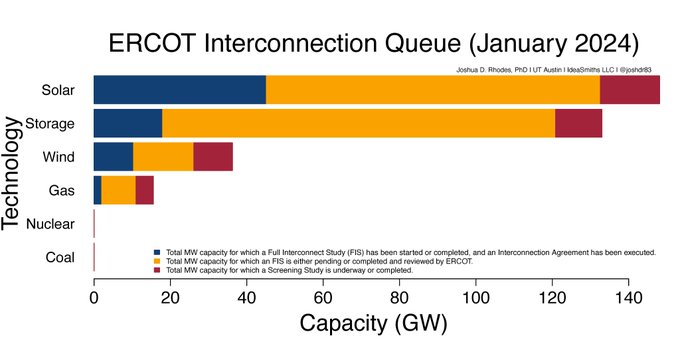

One example of this type of VPP is a new collaboration between Google spinoff Renew Home and NRG, which aims to become one of the largest thermostat VPP programs to date. Renew Home says 8.5 million Texas homes could yield 8.5 gigawatts of shiftable demand.

Pecan Street has been researching traditional and smart thermostat HVAC demand for more than a decade and has uncovered some particularly promising opportunities for thermostat based VPPs.

Summer Peak AC Driven Load

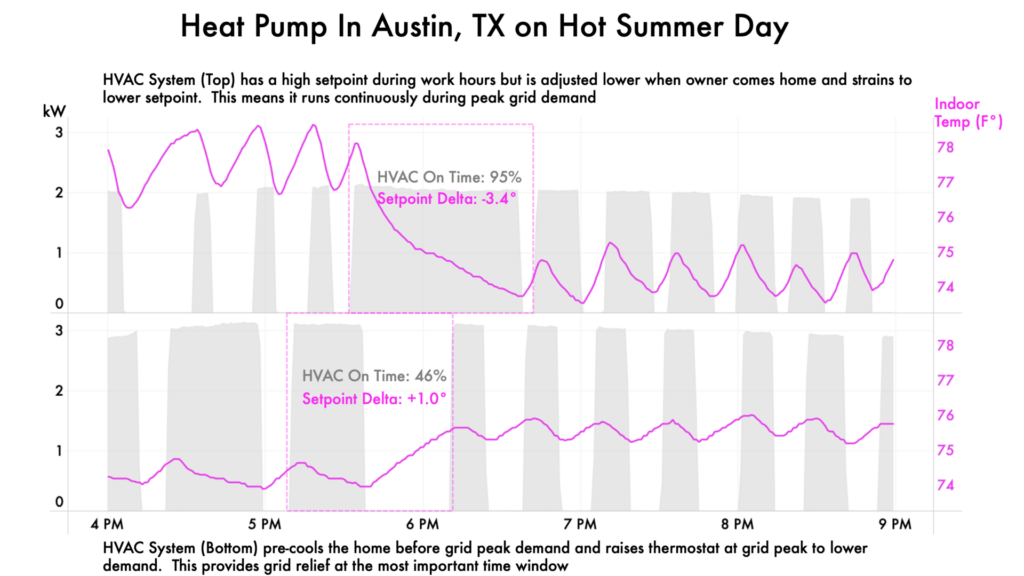

Consider the two homes below.

The first homeowner uses a “save energy” strategy many of our parents might have taught us. They significantly increase the thermostat setpoints when they’re not home. When they arrive, they crank up the A/C and let it rip. Notice how long the system runs. That continuous runtime negates much of the “energy savings” from earlier in the day and, more importantly, puts a significant strain on the grid at the worst time.

The other home (on the bottom) has constant setpoints and is programmed to precool during off-peak hours — when electricity is generally cheaper and the grid is under less stress — to lower the temperature in the home less than a degree below the thermostat setpoint. Then, during the peak-demand periods (often hot summer afternoons), the thermostat is set to the normal setting. As the house warms to the thermostat setpoint, the AC remains off. This precooling approach can create “cycle off’ periods for groups of homes that are staggered throughout the peak demand event to reduce the overall peak demand of the grid and minimize the warming impact of any particular home. This approach uses the home’s thermal mass and envelope to “store” cooler temperatures and keep the indoor environment comfortable without running the HVAC system at full power during peak hours.

Winter Peak Heat-Driven Load

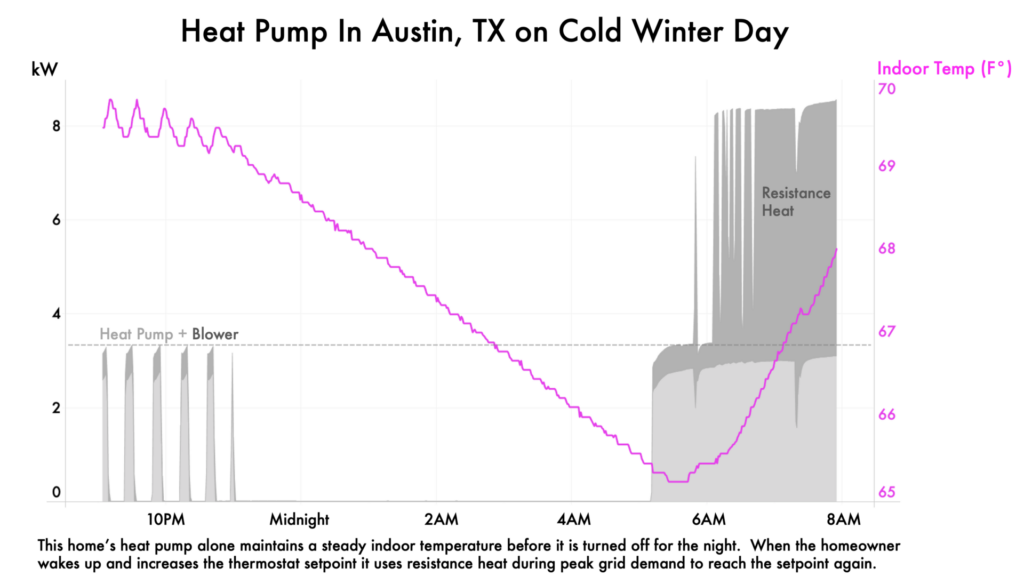

Similar to pre-cooling, pre-heating a home during winter peak can also be effective on cold winter mornings and evenings. However, another more impactful mechanism for controlling peak heating load is to reduce and flex the backup resistance heating in electric heat pumps.

Heat pumps move heat from outside to inside and are very efficient in mild winter weather. But when temperatures drop below freezing, this process can be slow. Many heat pump systems use backup resistance heat strips to directly produce heat to supplement the heat pump. Like a hair dryer, it blows air through coils that are heated to high temperatures with electricity. It’s quick, but it’s very inefficient.

When engaged to supplement the heat pump, backup resistance routinely draws 5-15kW of power – a massive draw that could be a demand response lever for VPP operators. This opportunity will only grow with the increased deployment of heat pumps.

If the thermostat setpoint rises too far above the indoor temperature (e.g. you wake up on a cold winter morning and raise the thermostat setpoint), the large temperature differential can trigger the backup resistance heat to help reach the target setpoint temperature faster. Backup resistance heat activation can be minimized at grid peak by keeping the home at a constant setpoint temperature and not changing setpoints during winter grid peak periods. Also, the temperature delta between the indoor temperature and thermostat setpoint that triggers the backup heat can be adjusted. If someone raises their thermostat setpoint a few degrees but doesn’t mind heating up the house slightly slower without assistance from resistance heat, this can provide major relief during periods of grid congestion. In ERCOT, winter peak demand is typically in the morning, before the sun rises, and evenings just after the sun sets.

Weatherization and Energy Efficiency

With a tight thermal envelope (insulation, windows, weatherization), a house retains its temperature from precooling or preheating for longer periods. This means that when the system pre-conditions the home ahead of anticipated peak demand, the indoor environment remains comfortable even as external conditions fluctuate. Homeowners experience no compromise in comfort, and utilities and grid managers can avoid calling on expensive peaker generation or appeals to conserve.

Similarly, backup resistance heat is not needed nearly as often in an energy-efficient home. Modern heat pumps are designed to operate efficiently even in colder climates thanks to innovations like variable-speed compressors, improved defrost cycles, and advanced refrigerants. These improvements allow heat pumps to extract and deliver heat more effectively when temperatures drop and keep backup resistance loads from stressing the grid at times of peak demand.

Apart from keeping us comfortable, our HVAC systems offer significant conservation and demand-shifting potential. The adoption of smart thermostats is far ahead of other distributed energy resources like home batteries and electric vehicles; when multiplied by the millions of homes with smart thermostats, the small energy shift from each home becomes a significant VPP resource. We’re excited by the potential and look forward to helping companies and utilities maximize it.